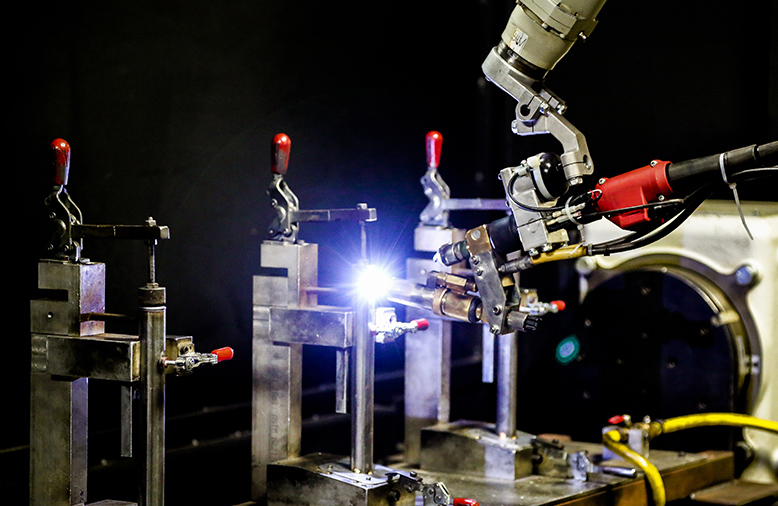

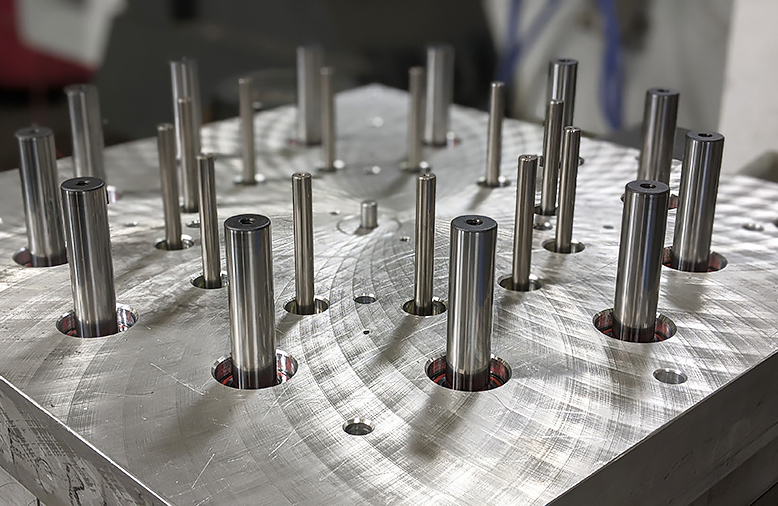

Few companies have the range of experience and capabilities available at O&A Manufacturing.

Our in-depth knowledge of engineering and tool making assures that customer projects will be well designed and thoroughly tested. Our modern medium- to long-run production capabilities assure that customers will get superior-quality products delivered on time and to specification – on everything from prototypes to production.