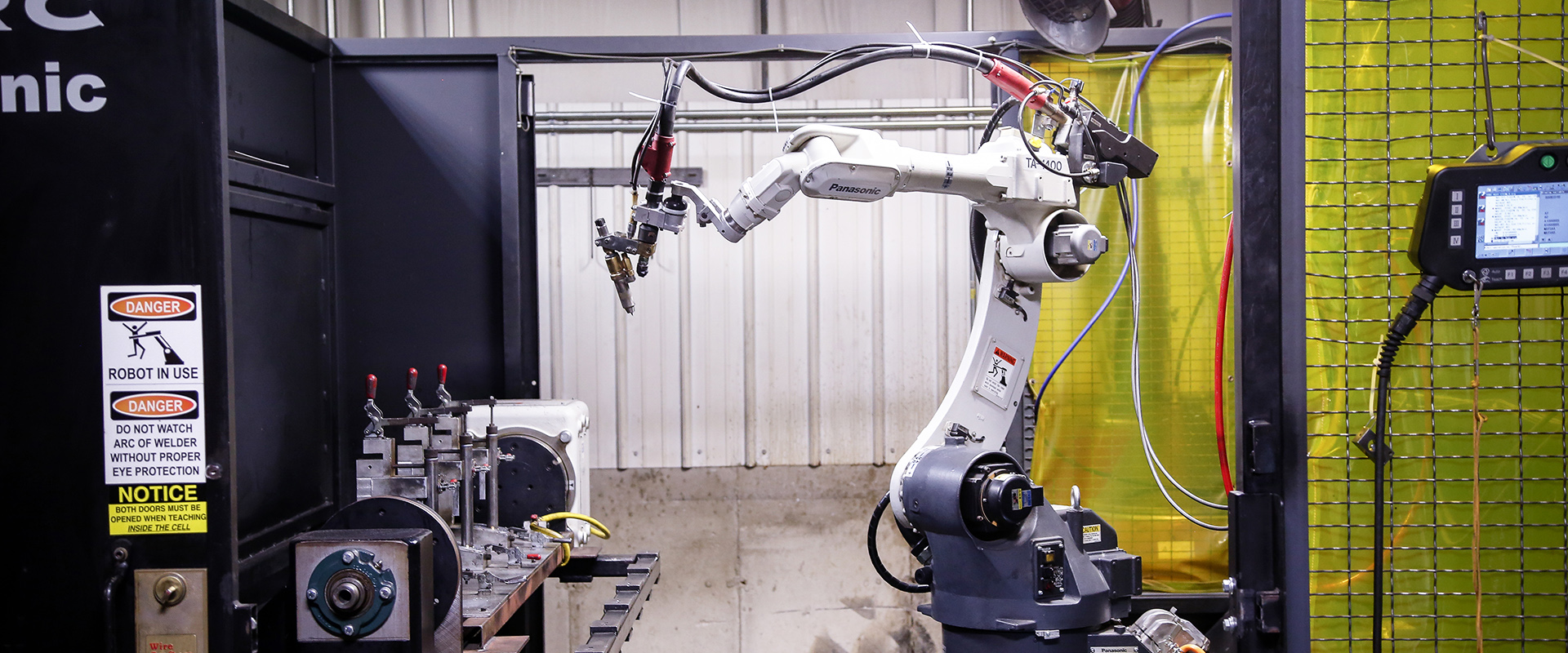

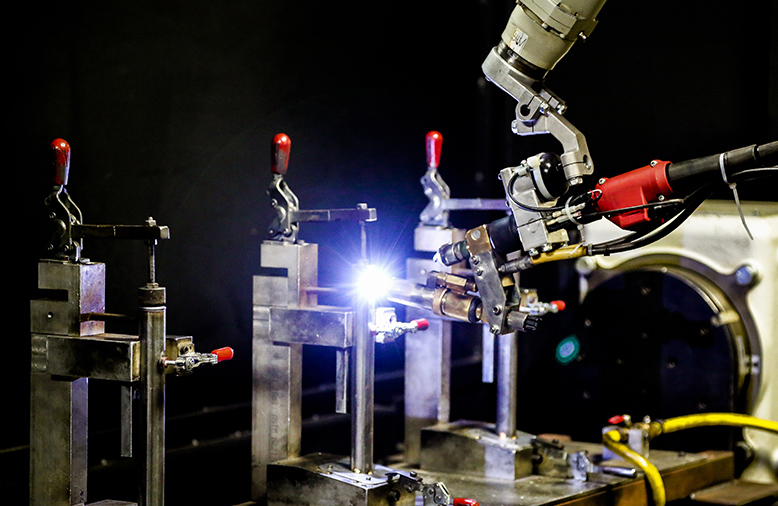

Welding:

O&A Manufacturing welds with a Panasonic Robotic Welder that has dual load & unload 28” x 58” Beds to accommodate an automatic operation while welding. On certain hand welding items several Miller TIG and MIG Welders are utilized. For spot welding requirement one of four machines can be used.

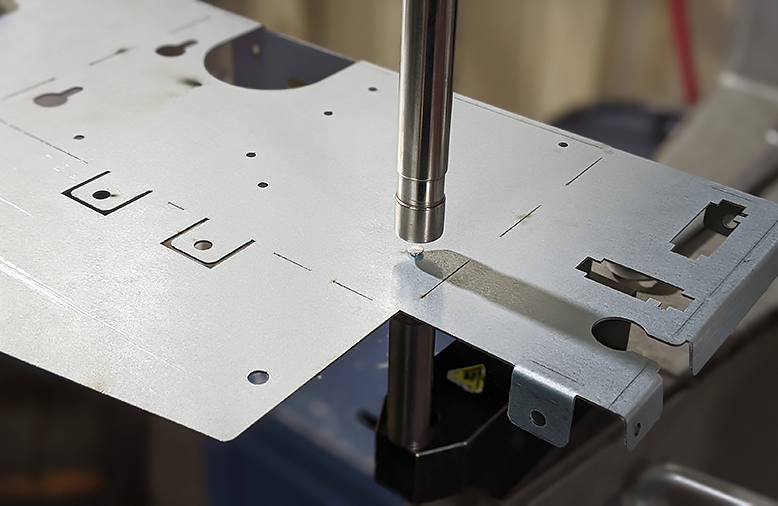

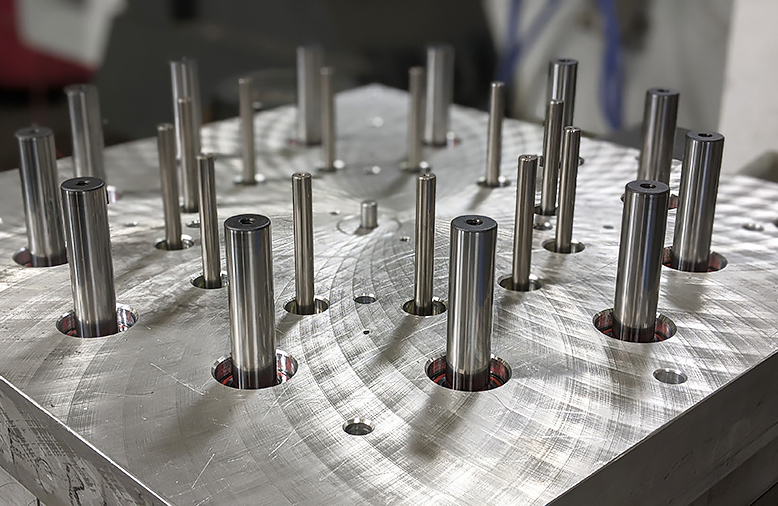

Tool & Die:

Our tool room is equipped with a variety of 3-axis CNC programmable mills and wire EDM. We offer complete in-house tooling and die-making services including:

- Custom Design and Prototype Development

- Rapid Turnaround Prototyping

- CAD-Engineered Die Design and Layout

- Precision Stamping and Forming Dies – Single Station to Multiple

- Progressive with Die Protection

- Wire EDM and CNC Machining

- Tool and Die Repair and Maintenance

Short-run machining and prototyping is also where O&A’s wire EDM capabilities come into play. Wire EDM provides precision cutting when extreme tolerances are called for. This capability also helps provide rapid turnaround on prototypes in a wide variety of materials.

O&A’s in-house tooling capabilities mean that we can launch new projects faster. They can also provide the kind of preventative die maintenance necessary to keep ongoing jobs running smoothly.

Pemming:

Fastener-installation equipment delivers a competitive edge. Holding strength is critically important on components and assemblies. O&A uses multiple pemserters to install industrial standard fasteners.