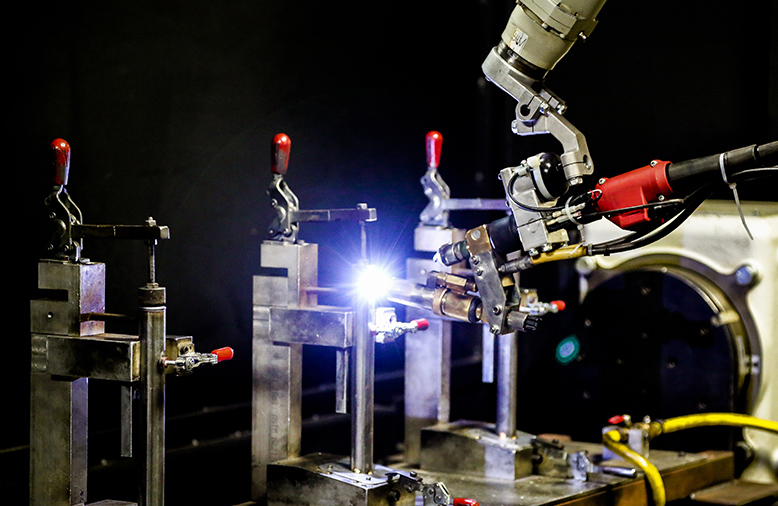

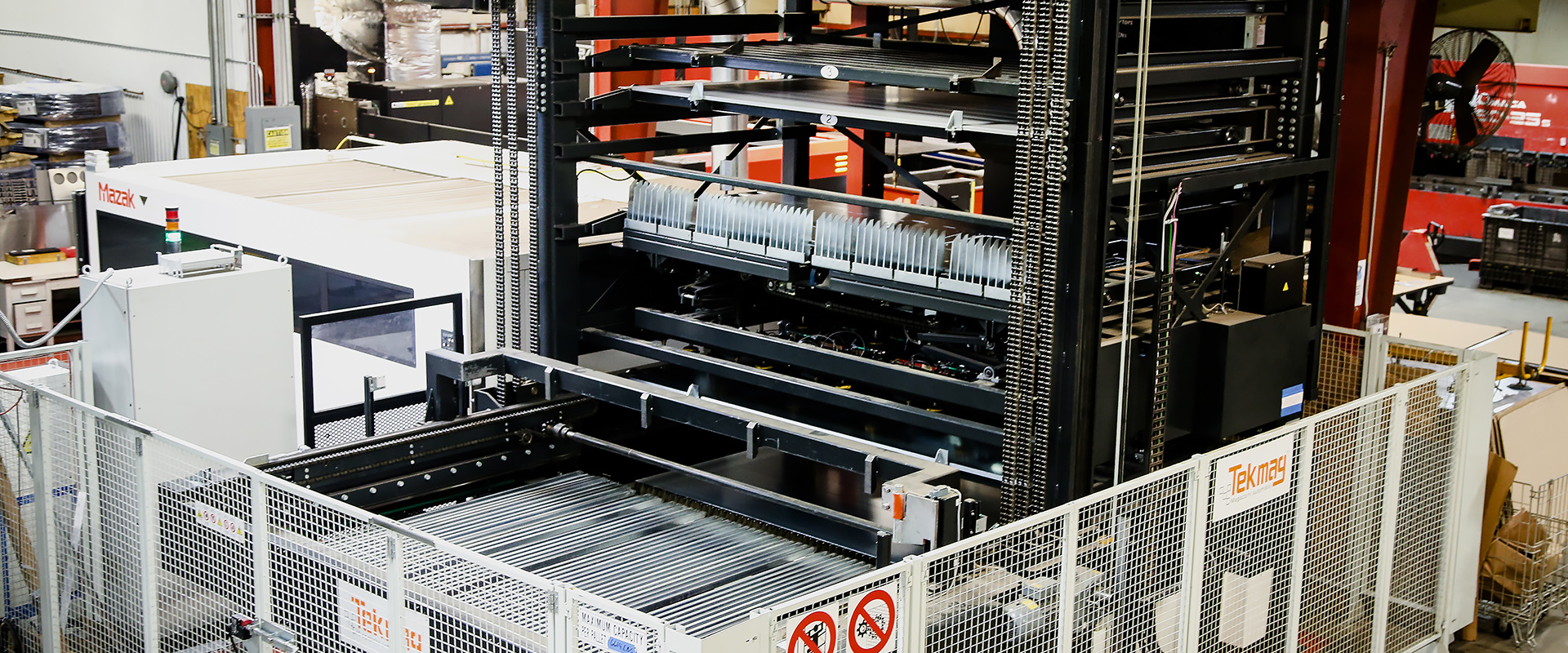

welding / tool & die / pemming

O&A Manufacturing welds with a Panasonic Robotic Welder with rotating bed that holds large and small fixtures. Miller TIG, MIG Welders and spot welders are also utilized for custom parts. Our tool room is equipped with a variety of CNC programmable mills, lathes and a wire EDM machine. We use multiple pemserters for fastener installation to create holding strength for a variety of products.